`` BRACU Duburi is participating in RoboSub 2022 ``

Our strategy for participating in RobotSub for the first time is "basics first; software over hardware." BRACU Duburi's broad plan for RoboSub 2022 is to focus on executing the most basic activities first with a simple design; only after refining the basics have we added additional functionality (and complexity) to our designs to enable it to complete the more sophisticated duties of the RoboSub course. Furthermore, we overcome our material and logistics constraints by selecting only the bare minimum of gear. To make up for that, we've spent a lot of effort and time into developing a solid computer vision and software control system.

Technical design Report AUV OverviewBracu DUBURI 3.0 Mechanical System

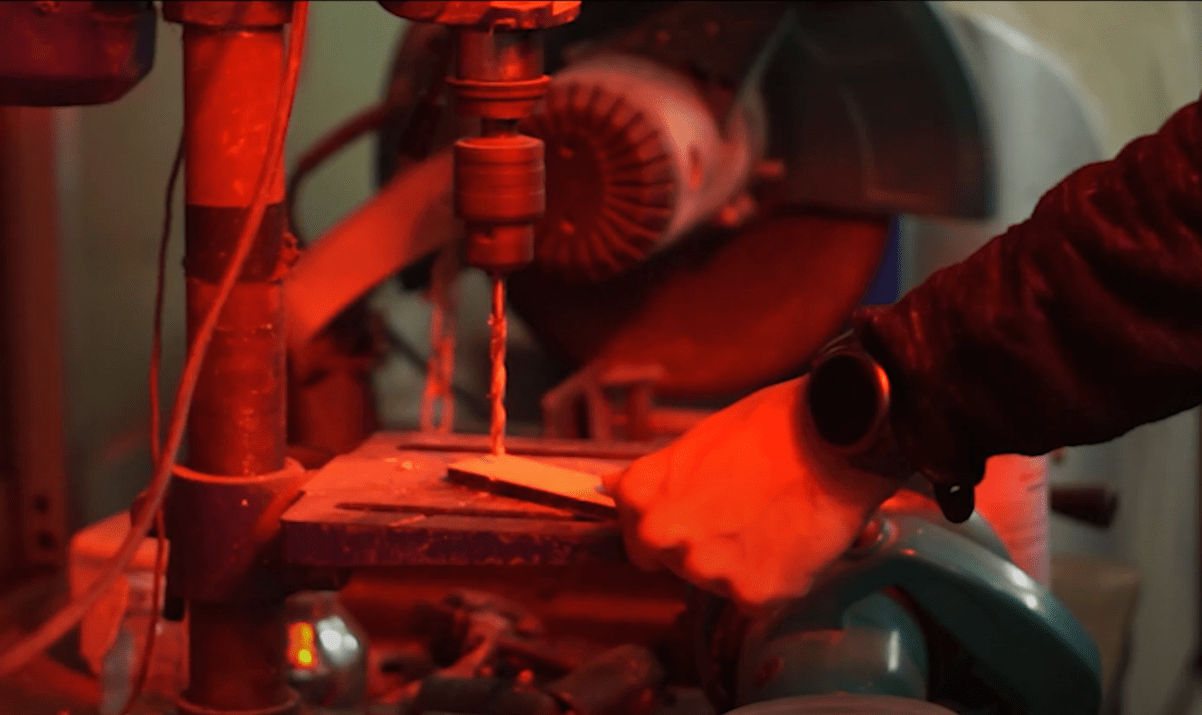

Duburi’s is designed in a manner that should allow it to withstand the pressures of 3 bars. Thus, the material chosen needs to have a very low weight-to-strength ratio to ensure that the AUV would be buoyant and have a max acceleration sucient for covering large search areas. 5083 marine-grade Aluminum was thus chosen over alternatives such as acrylic and plastic. This material has the additional benet of being suciently corrosion-resistant (even in salt-water environments), highly thermally conductive, widely available, and relatively easy to fabricate.

View MoreClick HereBracu DUBURI 3.0 Electrical Architecture

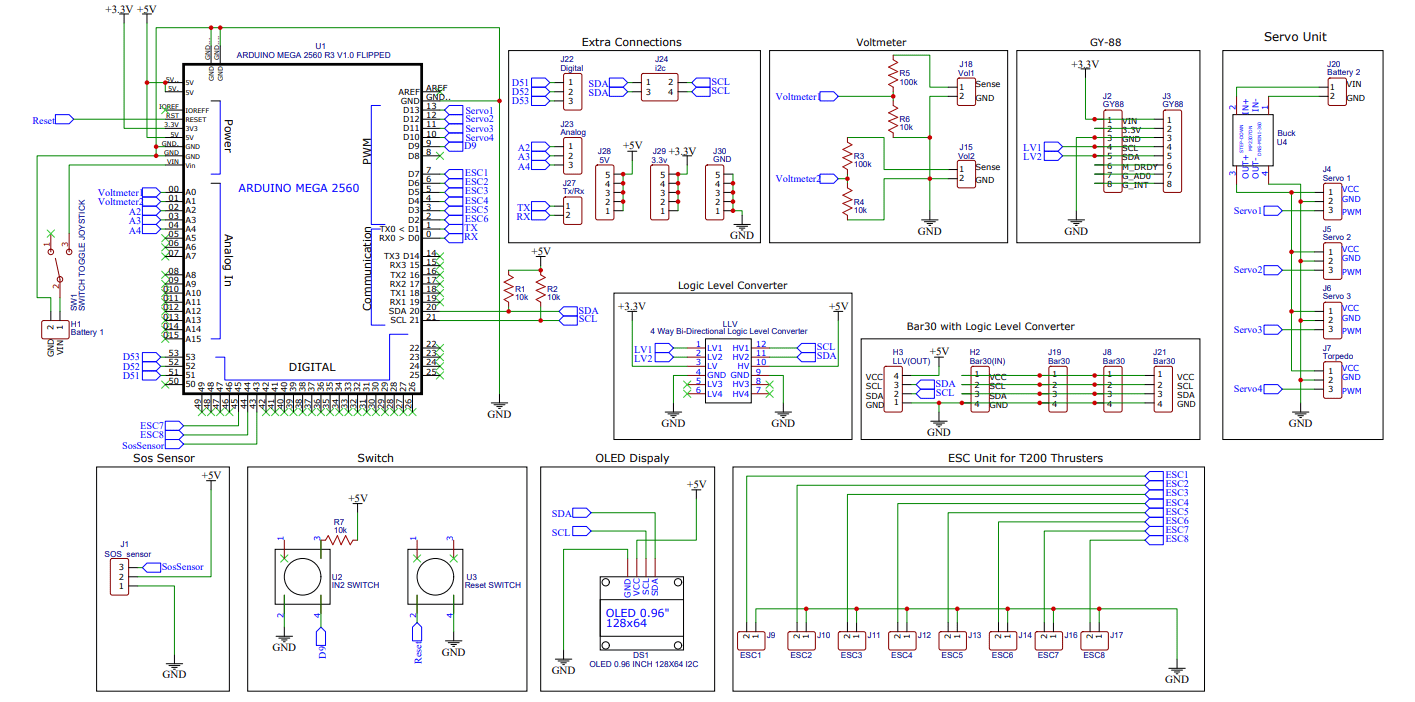

Duburi has its custom designed PCB that relays and connects all the sensors and electrical components keeping in component failures in mind. In order to swap sensors in case of failure. Apart from that also does not contain unnecessarily wiring.

View MoreClick HereBracu DUBURI 3.0 Software Architecture

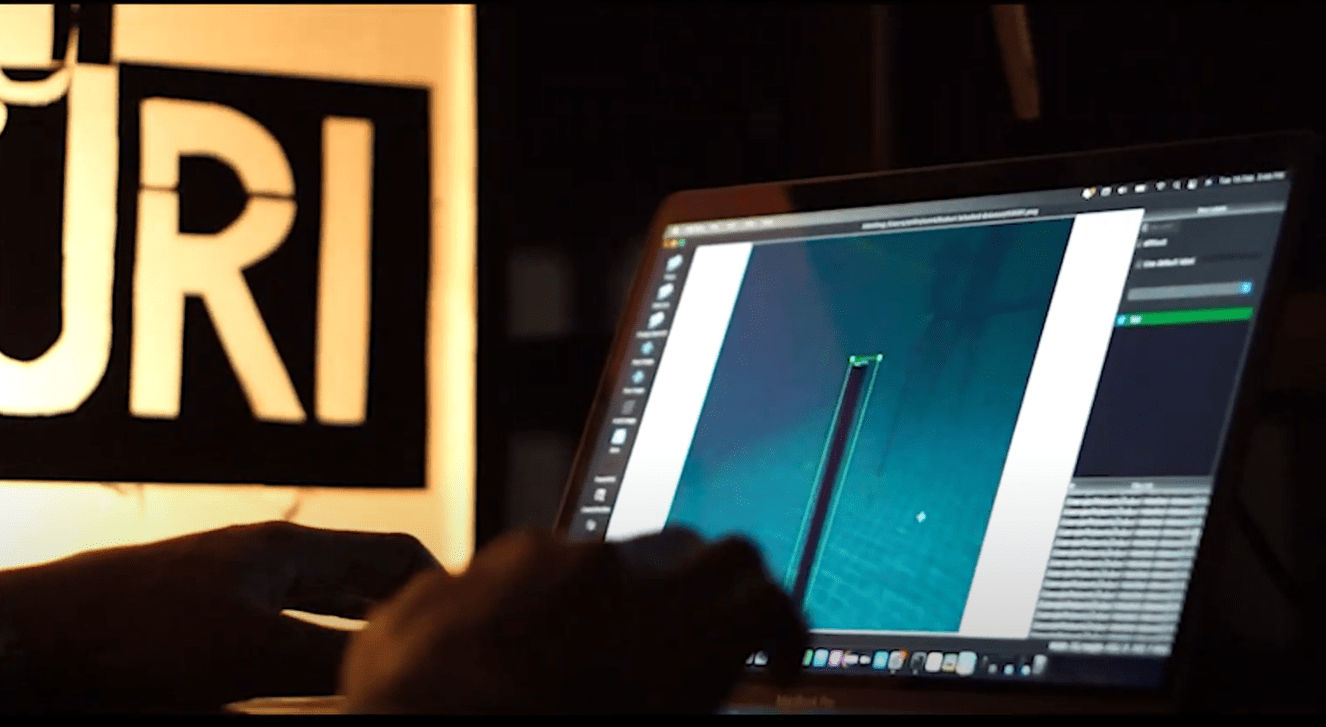

Duburi's Computer Vision subteam is in charge. Its job is to choose, train, and test Duburi's Machine Learning Algorithms for identifying objects underwater, which is an important aspect of Duburi's autonomous operation.

View MoreClick Here